After more than a month of dealing with tiny tweezers, rulers, PVA glue, sharpened pencils, sand paper, little brass jigs made to help cut bricks in perfect halves, Q-tips etc. etc. on the façade of my city house, I debated long and hard about whether the rear wall which faces a back alley would also be brick. Long and Hard!! Would my imaginary owner/builder decide to trim costs and maybe shiplap that back wall to save money? (Stickley’s plans left many decisions up to the home owner.) I mean, who would see it except for the city garbage collector? After watching hours of “Friends” re-runs with my granddaughter, the idea of a fire escape came to mind. The decision to brick that rear wall was made. How cool would that look? Done!

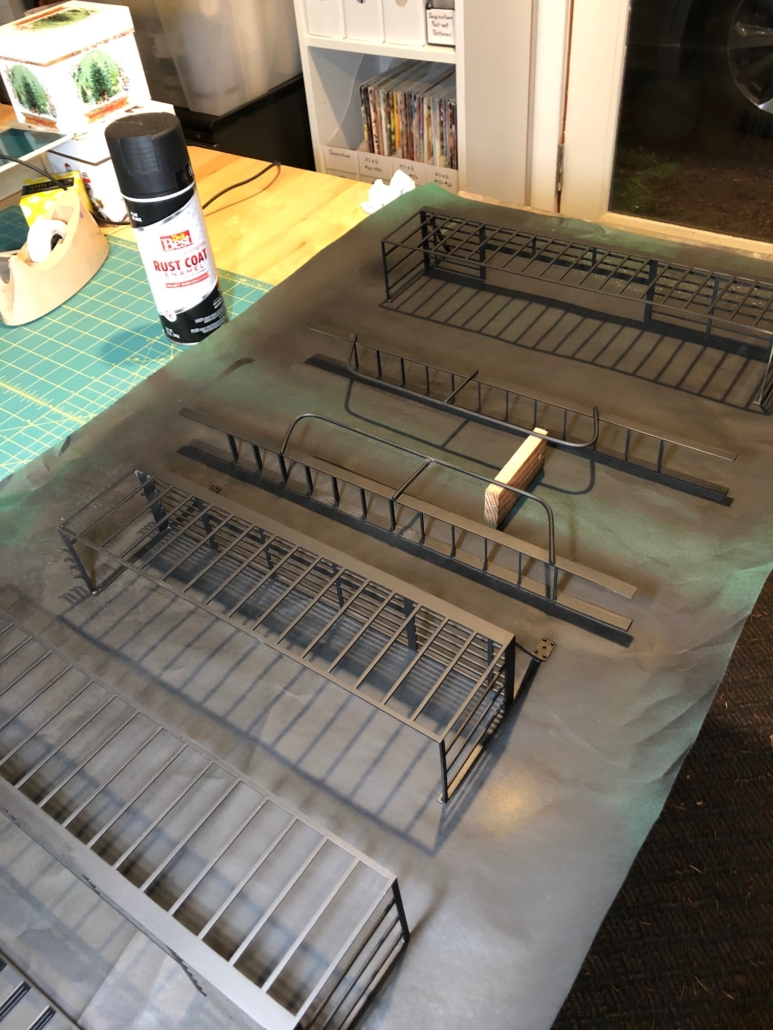

I bricked the entire wall. It was much easier and faster than the front wall that had indentations, decorative brick patterns in those recesses and curved porch elements. Tricky. With the rear wall bricked, then came the metal components. On the façade, I had hand cut the (“sleeping porch”) balcony railing by hand with my jeweler’s saw out of 14ga brass. It turned out fine but was a real physical effort. I couldn’t imagine cutting all that brass by hand for the fire escape that I had designed. Bob Powell of Vashon (Metal@MetalCreature.com) advertises in our local Beachcomber newspaper that he does “art fabrication” (and a lot of other things) with abrasive waterjet machining. I drafted the panels, Bob cut my pieces, and all I had to do was silver solder everything together. After sand blasting, painting and mounting, I’m more than happy with the results.